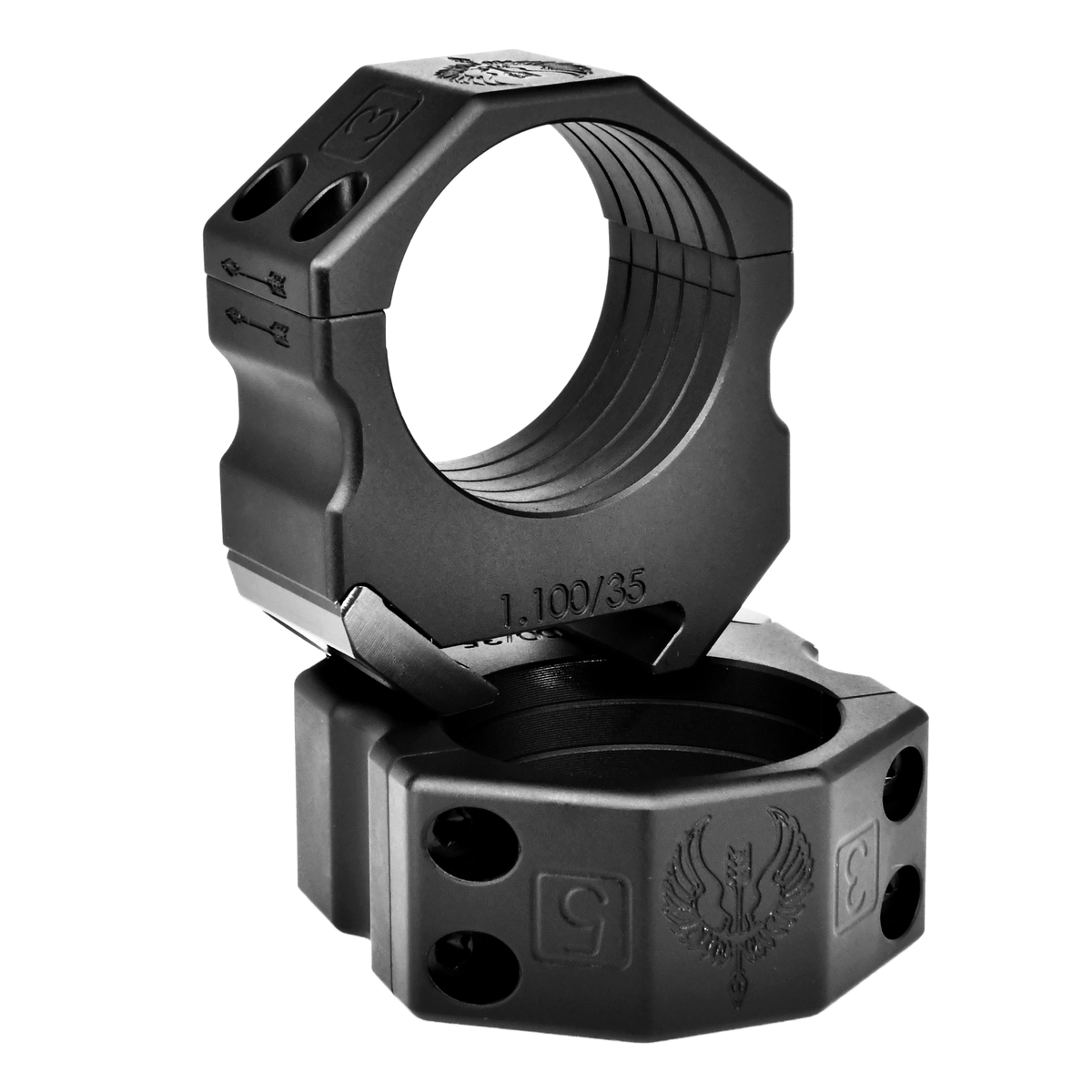

35mm Scope Rings

When looking at the market for premium scope rings there are a lot of variables. It's an accessory that often gets overlooked but it's certainly one that shouldn't be. This is because your optic is your connection to the target and the scope rings are your rifle connection to your optic. So, what's different with American Precision Arms Gen 2 Tru-Loc Scope Rings.

Differences From Other Scopes Rings

First are weight and strength. 99% of scope rings are either steel cast, MIM, or aluminum. Steel is a great option, but it is heavy. Not only is it heavy, but it's heavy in an awkward area, no one wants a top-heavy rifle. Cast and MIM parts are just no good. They are riddled with unseen voids and simply have no place in the realm of premium parts. This leaves aluminum. It's important to note that not all aluminum is created equal. The majority of aluminum alloys are not up to the task. Most "higher-end" aluminum scope rings are made from 6061 aluminum, which is often referred to as “aircraft-grade aluminum”. The reality is, though 6061 is used in parts of an aircraft, it's never used on the wings, turbines, or hull; the important parts where maximum strength is required. Only the highest strength aluminum, 7075 T6, is called upon for these tasks. 7075 T6 is nearing twice the strength of 6061 and is the only aluminum alloy found on American Precision Arms Scope Rings.

Next is latch design. One thing you can say about the vast majority of last designs that incorporate with a Picatinny rail is that they are all the same. They all have a latch that comes in from the side, camming onto the undersurface of the Picatinny rail. For the most part, it works pretty well but it does raise a couple of issues. The first issue is repeatability. The standard latch is not repeatable because it is torque-sensitive. The second issue that arises is strength. Just because there's a big cross-bolt does not mean that it's strong. The Tru-Loc latch system doesn't come from a lateral angle that leaks strength due to the lack of direct tension on the rail.

Instead, first, the Tru-Loc latch system applies tension directly to the rails mating surface. That means whether you tighten it 10 inch-pounds or 47.2 inch-pounds it will secure the scope and the same precise location every time always returning to zero. Secondly, it applies strength where strength is needed. It avoids bulky screws and bolts that don't address the real issues.

APA holds the tightest tolerances in the industry. That means there are no match sets, and every ring is checked on state-of-the-art optic technology. Our sizes are specifically marked so that you know the height you are getting. The numbers specify the distance from the top of your Picatinny rail to the cross-section of the bore of the scope.

Major Takeaways

The APA Gen 2 Tru-Loc Scope Rings are among the strongest in the world due to their unique design, premium materials, and unmatched build quality. They possess the ability to return to an infinite zero because of the engineering geometries utilized. American Precision Arms is proud to introduce the Gen 2 lineup of Tru-Loc scope rings.

Available in three different heights .950, 1.100 & 1.250

Our rings weigh 3.8 - 4.4 oz per set depending on the height selected

Torque Specifications

Caps - 20 inch pounds

Latches - 25 inch pounds